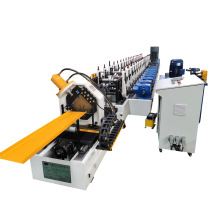

Máquinas de formação de rolos, METAL press forming machine

Descrição do produto

Especificação principal e componentes

1.Main Especificação

NO. |

main parameter |

|

1. |

Suitabale to process |

Steel plate |

2. |

Width of the plate |

1250mm |

3. |

Rollers |

13 rows |

4. |

Dimensions |

6.5*1.5*1.2m |

5. |

Power |

5.5kw+4kw |

6. |

Thickness of the plate |

0.20.8mm |

7. |

Productivity |

12m/min |

8. |

Diameter of the roller |

75mm |

9. |

Weight |

6.3T |

10. |

Voltahe |

380v 50Hz 3phase |

2. Especificação dos componentes

|

NO |

Technical Specification & Remark |

|

1 |

1 Uncoilewithout motion |

Functionbear color steel coil and feed material for forming machine |

|

2 |

1 Feeding platform |

,. Function and featureput the raw material(steel plate) on the plate to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity. |

|

3 |

1 Main machine |

,,,,,,,,,. In order to keep the product shape and precision,adopts welded sheet strecture, motor reducer drive,chain ansmission, roller surfaces polishing, hard planting,heat treatment and galvanization treatment. The polished sufaces and the heat treatment towards the roller also can be keep the plate suface smooth and not easy to be marked when it is being stamped. 0.05mm Rolling galvanization thickness:0.05mm 45# Rolling material: Forging Steel 45# |

|

4 |

1 Shearing mechanism |

,. It adopts the hydraulic drive and automatic location to decide to dimension and cut the target products. 22,2. It contains two set of cutting tools,two hydraulic tank and one cut machine. Cr12 Material of the cutting blade: Cr12 2 Number of the cutting tool: two sets |

|

5 |

1 Hydraulic system |

,,,. It is controlled by gear wheel oil pump.After filling the hydraulic x into the hydraulic oil tank,the pump drive the cutter machine to being the cutting job. ,.,. The system includes a set of hydraulic tank,a set of hydraulic oil pump,two hydraulic pipes,And one set of electromagnetism vales. |

|

6 |

1 Computer control cabinet |

,,.,,. It adopts industrial computer control.The target pieces length can be adjustable and digit ot it can be adjusted.Compyter mode has two modes:automatic and manual one.The system is easy to operated and use. ±2.00mm Processing precision :within ±2.00mm It contains lipuid crystal screen, programmer, transfomer of the electronic machines and kits of every part. , There are control buttons,separately control every layer. The screen with the Chinese and English two languages 2,,. Two counter gauges length, pulses,and decides length. |

7 |

1 Dischange table |

. To receive production |

Grupo de Produto : Máquina de Purline de C & Z